WINDS OF CHANGE

The SouthCoast region is experiencing a remarkable surge in technological innovation within the offshore wind energy sector. Cutting-edge advancements in wind turbine design, installation techniques, and grid integration are revolutionizing the region’s energy landscape. Spearheaded by local research initiatives, these developments promise not only to generate clean energy but also to bolster job creation and drive sustainable growth. With new projects on the horizon, the SouthCoast is at the forefront of pioneering technologies that are propelling us into a new era of sustainable energy production.

Vineyard Wind 1 Offshore Wind Energy Project

Vineyard Wind is currently building the nation’s first utility-scale offshore wind energy project. The project will consist of 62 turbines that generate renewable energy for over 400,000 homes and businesses across Massachusetts, while reducing carbon emissions by a projected 1.6 million tons per year.

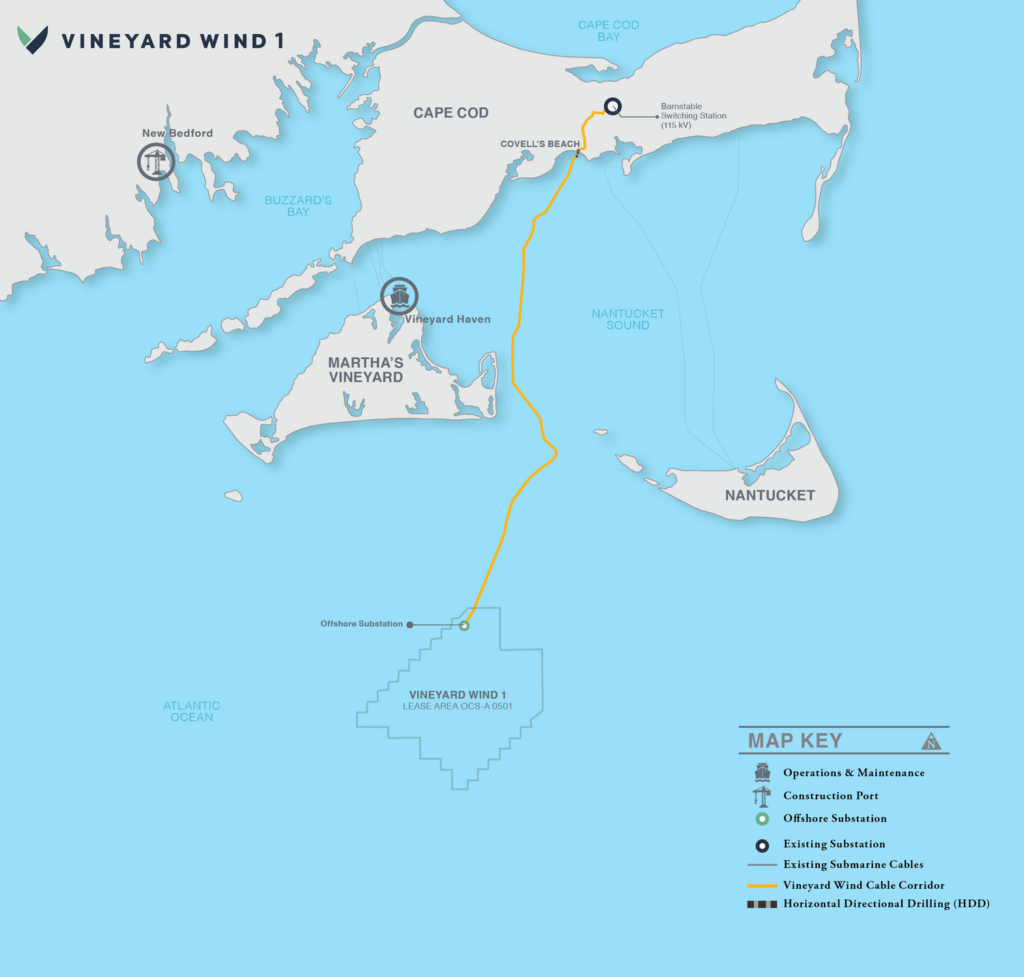

Vineyard Wind 1 is located in federal wind energy area OCS-A-0501, 15 miles south of Martha’s Vineyard and Nantucket, and 35 miles from mainland Massachusetts. The location was determined through a multi-year, intergovernmental task force process, which carefully considered scientific data and public input. This area was selected for its powerful, reliable wind speeds and ideal site conditions to support wind turbines. The turbines will be located on an east-to-west grid spaced at least one nautical mile apart.

Vineyard Wind is demonstrating that large-scale clean electricity generation can go hand-in-hand with environmental protection and greenhouse gas emissions reduction to meet Massachusetts and the United States ambitious renewable energy goals and effectively combat climate change. Wind power plays a pivotal role in solving the climate crisis and will reduce carbon emissions by millions of tons each year protecting people, animals, and ecosystems that call earth home.

The New Bedford Marine Commerce Terminal was engineered specifically to support offshore wind projects and is currently storing and assembling components for the Vineyard Wind 1 project. These pieces include massive tower sections, football-field-sized blades, and the nacelle that holds the generator atop the tower. Specialized vessels bring these components here for assembly. From New Bedford, feeder vessels then transport them to the wind farm sites. The terminal employs hundreds of skilled union workers, making New Bedford a leading hub for the emerging offshore wind industry in the United States.

Harnessing Wind Energy

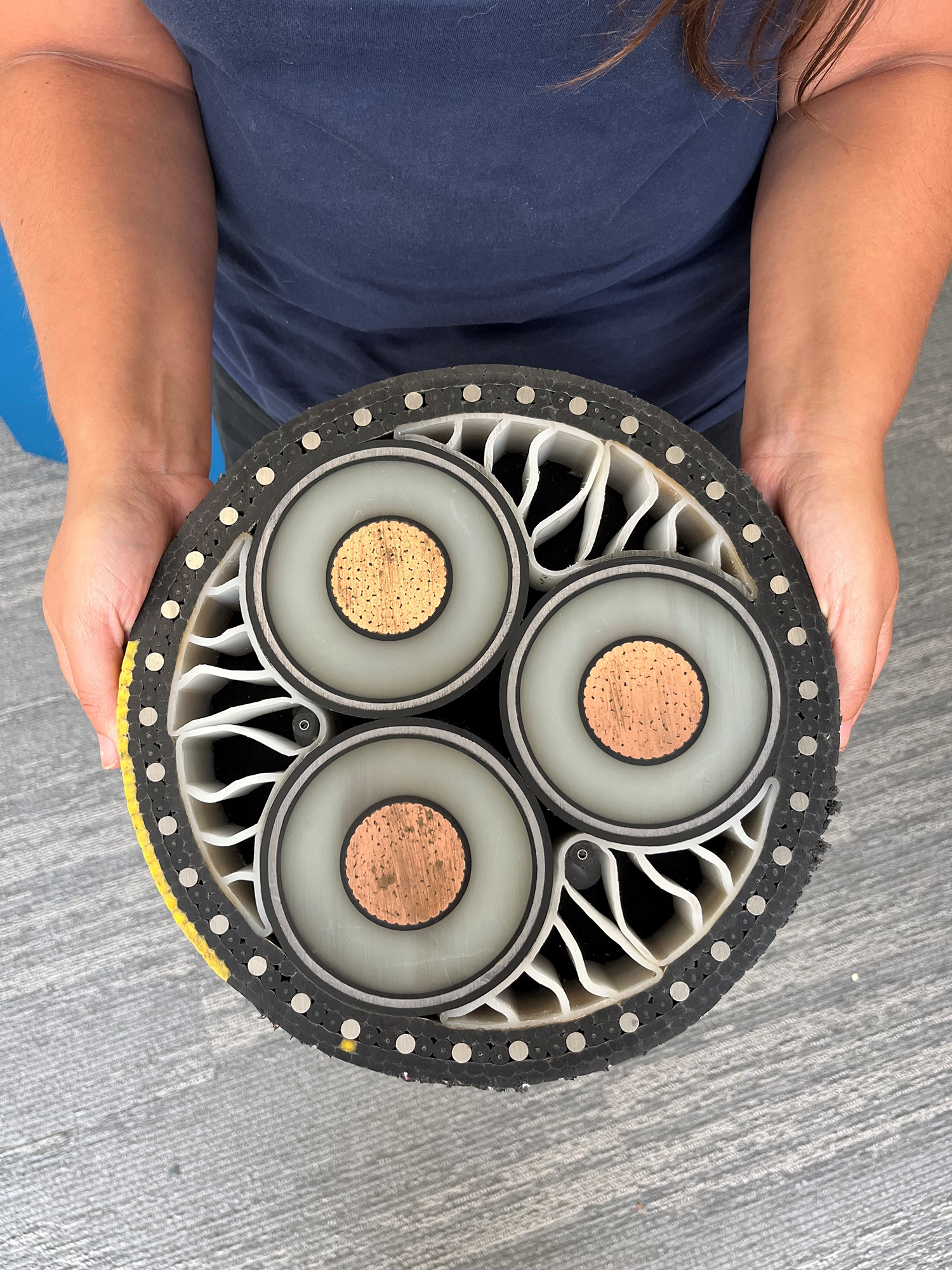

Vineyard Wind 1 turbines capture the wind’s energy through spinning rotor blades that turn the generator inside the turbine to produce electricity. The energy generated is then transmitted by cables beneath the ocean floor to an offshore substation, where it’s consolidated and sent to shore via two large sub-marine cables. Once onshore, it integrates with the local electrical grid and is distributed to homes and businesses across Massachusetts.

The electrical service platform (ESP) is the largest piece of equipment in a wind farm. Standing almost 300 feet on the ocean floor and weighing over 5,000 tons, it is the central hub where the electricity generated by the turbines is collected, transformed, and transmitted to the onshore grid.

A cross-section of an underwater export cable showing high-voltage conductors surrounded by layers of protective armor and insulation to withstand the harsh marine environment.

Building, transporting, and installing these massive structures offshore requires specialized vessels, the latest technology, and innovation to ensure safe and sustainable development of offshore wind projects. The 650 ft. heavy-lift vessel Orion is able to lower and stabilize its legs onto the ocean floor to install the foundation and transition pieces.

The SEACOR HAWK is the lift boat that workers lived on during the installation and construction of the electrical service platform (ESP). This jack up vessel has large legs that extend down to the sea floor, allowing it to raise itself above the water level and for workers to easily access the ESP.

Environmental Protection

PARTNERING WITH THE UMASS DARTMOUTH SCHOOL FOR MARINE SCIENCE AND TECHNOLOGY (SMAST) & UNIVERSITY OF NH

Fisheries related surveys, studies are essential to offshore wind development. Vineyard Wind is using visual, acoustic, thermal, and emerging technologies to monitor protected species throughout all phases of the project. Partnering with the University of New Hampshire, Vineyard Wind has deployed the above pictured Passive Acoustic Monitoring (PAM) device. These record marine mammal species and ocean sounds, allowing scientists to better understand whales’ behavior and their interactions with human activities like offshore wind farm construction.

Together with SMAST, Vineyard Wind conducts ongoing surveys, examining highly migratory species, lobster, black sea bass, and plankton, to collect baseline data on commercially important fish species.

Explore ongoing surveys and research & learn more about Vineyard Wind’s Fisheries Science partners below:

T-Omega Wind

Fisheries related surveys, studies are essential to offshore wind development. Vineyard Wind is using visual, acoustic, thermal, and emerging technologies to monitor protected species throughout all phases of the project. Partnering with the University of New Hampshire, Vineyard Wind has deployed the above pictured Passive Acoustic Monitoring (PAM) device. These record marine mammal species and ocean sounds, allowing scientists to better understand whales’ behavior and their interactions with human activities like offshore wind farm construction.

Together with SMAST, Vineyard Wind conducts ongoing surveys, examining highly migratory species, lobster, black sea bass, and plankton, to collect baseline data on commercially important fish species.

Expanding Possibilities for Wind Power

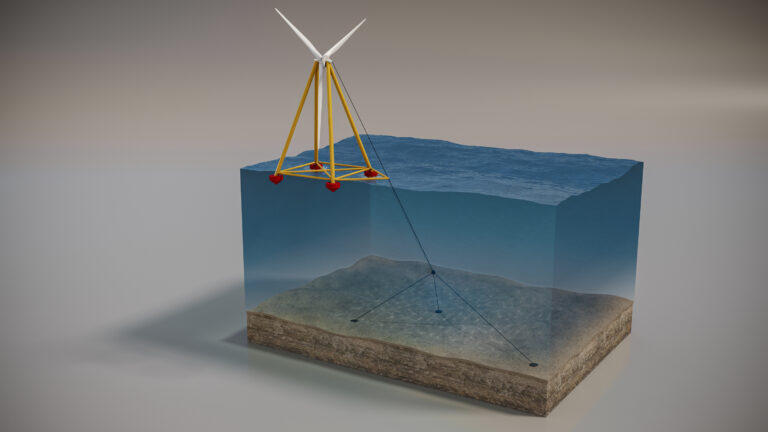

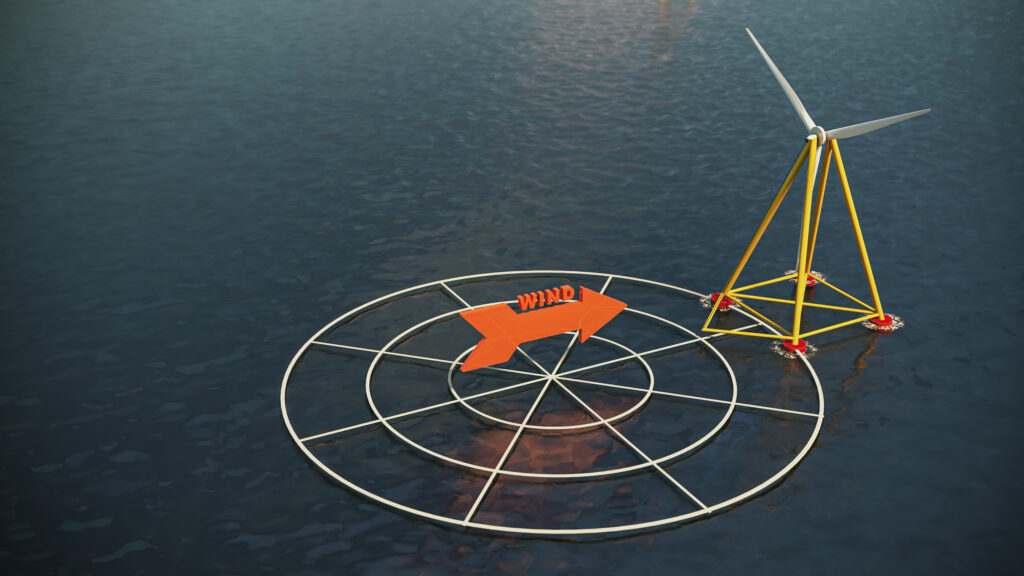

T-Omega Wind is revolutionizing offshore wind turbine design with its proprietary floating platforms, which capitalize on the natural advantages of being on water. The system floats in shallow or deep water, and rides on top of the waves rather than resisting them. Its rotor is held firmly on both sides, and aligns to the wind by weather-vaning like a ship at anchor. This accommodates for the motion and accelerations of the ocean in new and novel ways.

T-Omega Wind launched the 1/16 scale demonstrator turbine in Clarks Cove in New Bedford, MA on Monday, December 4, 2023. The demonstrator unit captured data and insights over 60 days.

DESIGN IMPACT:

T-Omega Wind’s 1/16 scale turbine operating off the coast of New Bedford was launched in December 2023. This 39-foot-tall demonstration unit validated structural stability, wave following motion, and force on the anchor & mooring lines. The next step for the company is a commercial scale pilot unit, to be connected offshore to the grid in the U.S.

– Light-weight – Deployability – Easy manufacture – Towability

The unique design is specific for the ocean environment, created to be manufactured and assembled utilizing domestic work forces, at existing ports. By allowing wind yawing around the anchor, the turbine can use a lighter, more efficient tower and support. The standard horizontal-axis rotor eliminates a large percentage of material costs for the support structure and platform. These significant savings in capital and operating expenditures have been third party verified, and will positively impact costs for both offshore wind developers and electric utilities.

At full utility scale, each turbine can power over 4,000 homes (44,000 MWh at 50% capacity factor). Each single turbine suppresses the carbon equivalent of removing 9,000 gas powered vehicles per year.

T-Omega Wind technology opens up vast areas of ocean wind energy that cannot be utilized by traditional legacy wind turbines. The company is dedicated to the mission of providing renewable energy as a right of all people, globally.

Learn more about the pioneering design behind T-Omega Wind’s floating offshore wind turbines at t-omegawind.com